Jun. 28, 2024

The CNC tool rest is an indispensable electromechanical equipment in industrial production and a very common auxiliary device in CNC machine tools.

The tool rest system of CNC lathes mainly includes rotary tool rests, row tool rests and automatic tool change devices with tool magazines.

The following is a brief introduction to these three types of tool rests.

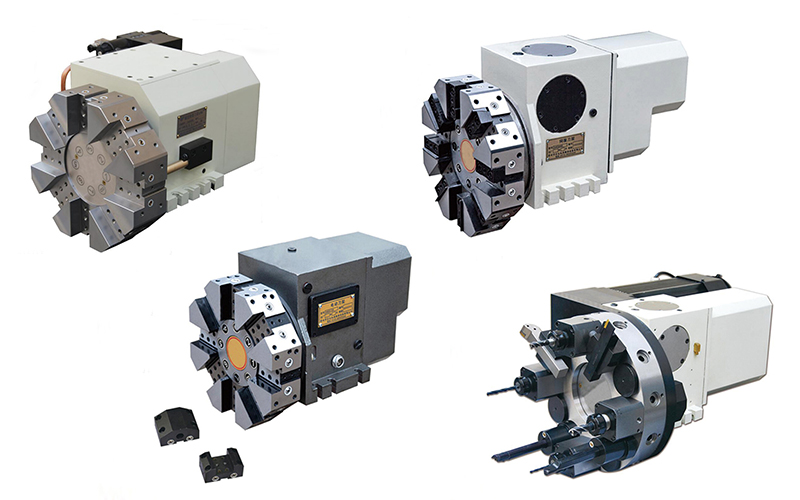

1. The rotary tool rest is a very common type of CNC tool rest and a typical tool changer commonly used in CNC lathes. Generally,

the automatic tool change action of the machine tool is realized through a hydraulic system or electrical.

According to the processing requirements, it can be designed into a square, hexagonal or disc tool rest, and 4, 6 or more tools can be installed accordingly.

The tool change action of the rotary tool rest can be divided into several steps, such as tool rest lifting, tool rest rotation and tool rest locking.

The rotary tool rest is divided into two types: vertical tool rest and horizontal tool rest according to the relative position of the tool rest rotary axis and the installation bottom surface.

2. The row tool rest is mainly used for processing bar or disc parts. It is a type of CNC tool rest generally used for small-sized CNC lathes.

Its structural form is: the tool holders holding various tools for different purposes are arranged on the horizontal slide along the X-axis direction of the machine tool.

This tool holder is convenient in terms of tool arrangement and machine tool adjustment.

It can arbitrarily combine various tools for different purposes according to the turning process requirements of the specific workpiece.

As long as the horizontal slide moves along the X-axis for a preset distance according to the program,

the second tool will reach the processing position, thus completing the tool change action of the machine tool.

3. Automatic tool changing device with tool magazine. The above-mentioned tool rack and rotary tool rack cannot be equipped with too many tools.

Even if two tool racks are equipped, when a large number of tools are required for some reason,

an automatic tool changing device with tool magazine should be used. The automatic tool changing device with tool magazine consists of a tool magazine and tools.